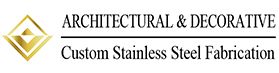

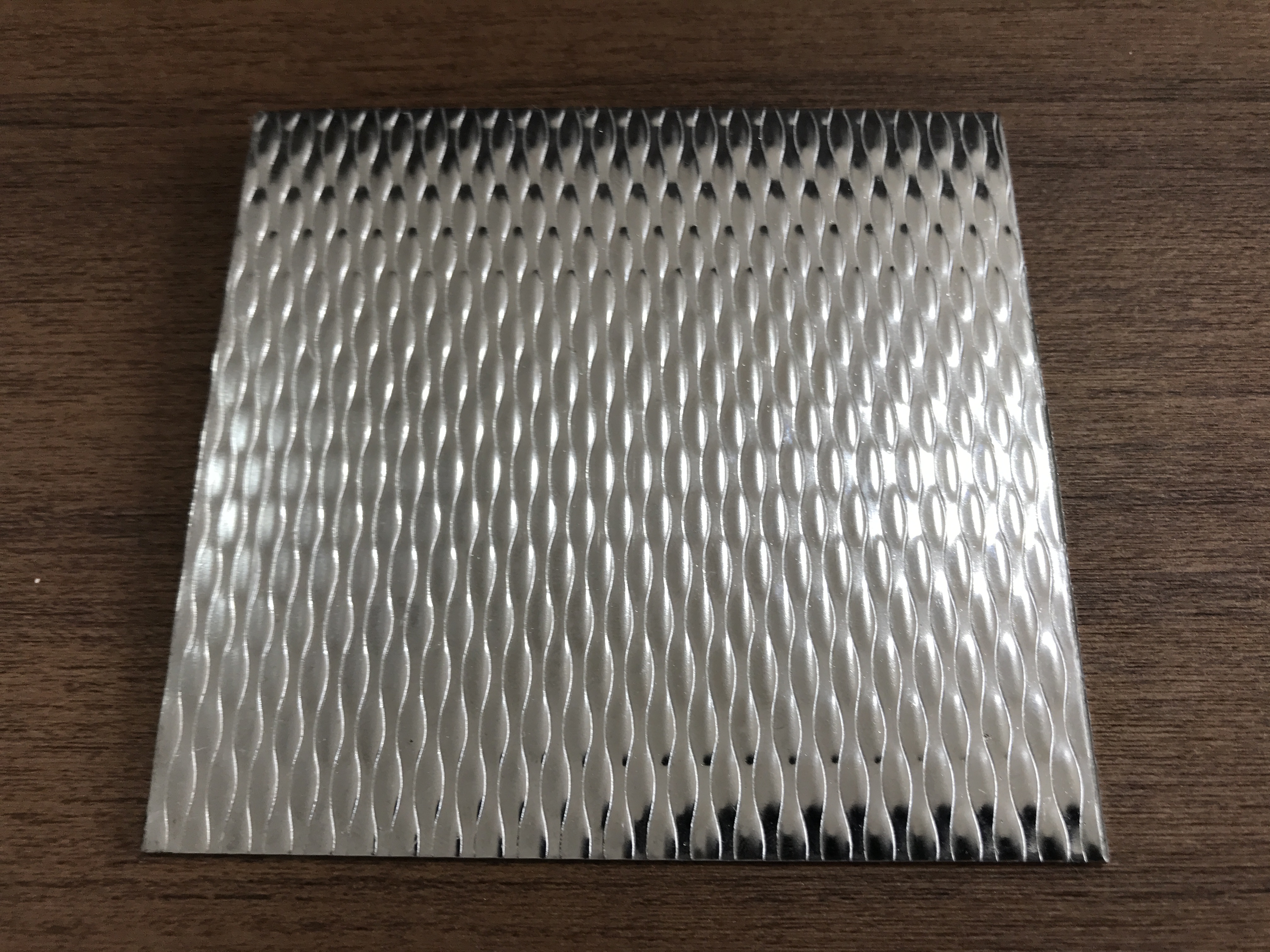

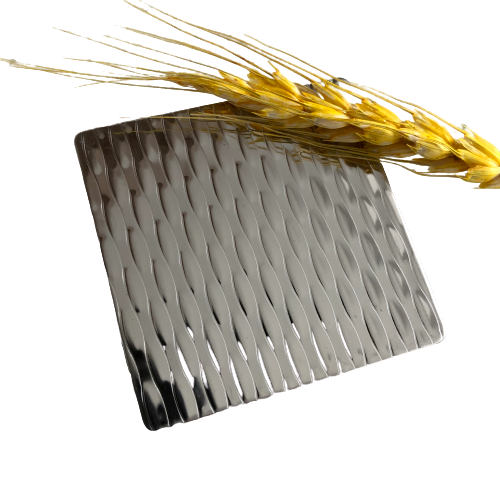

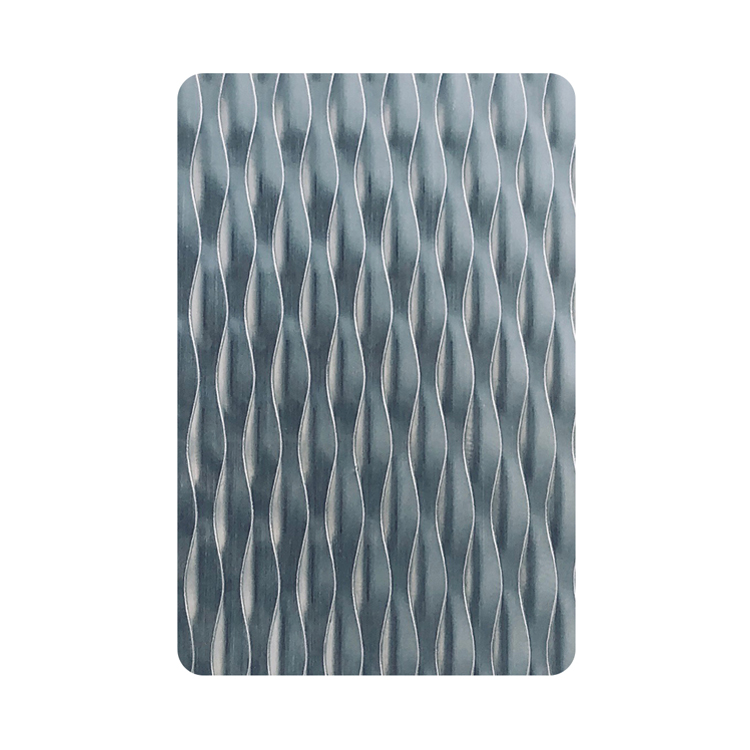

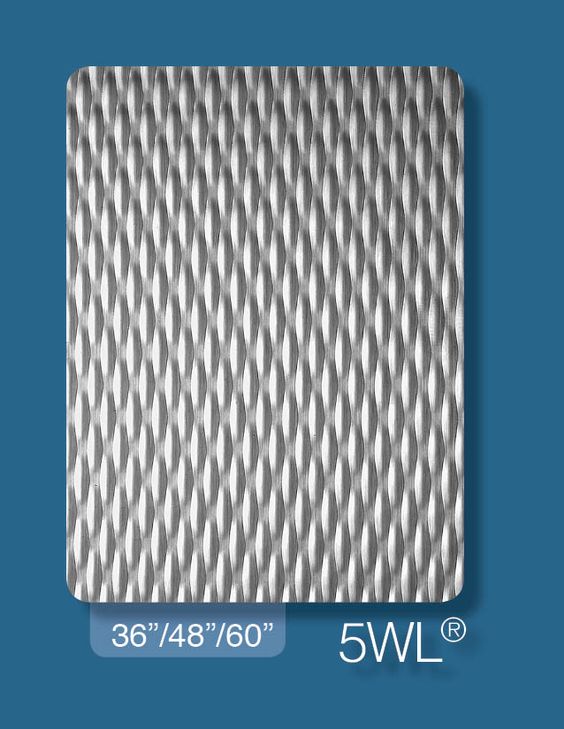

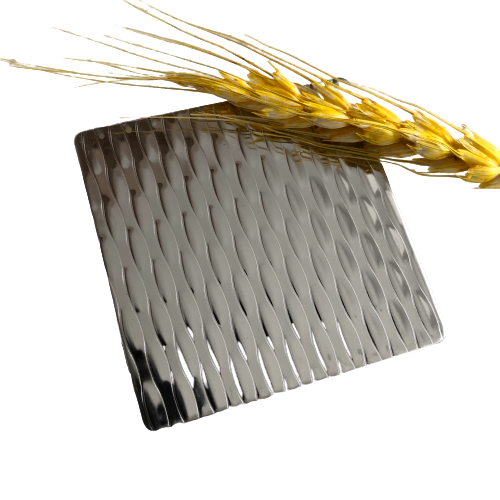

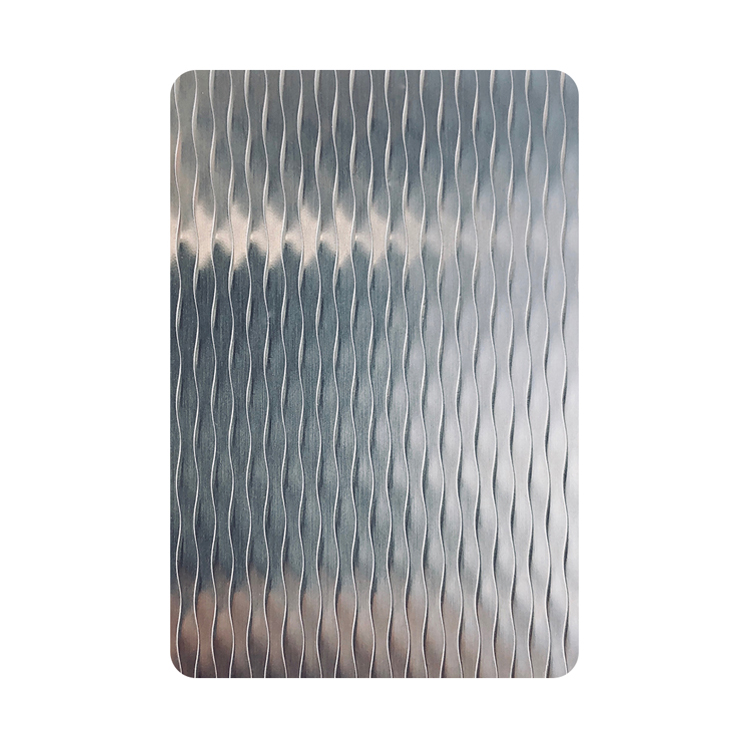

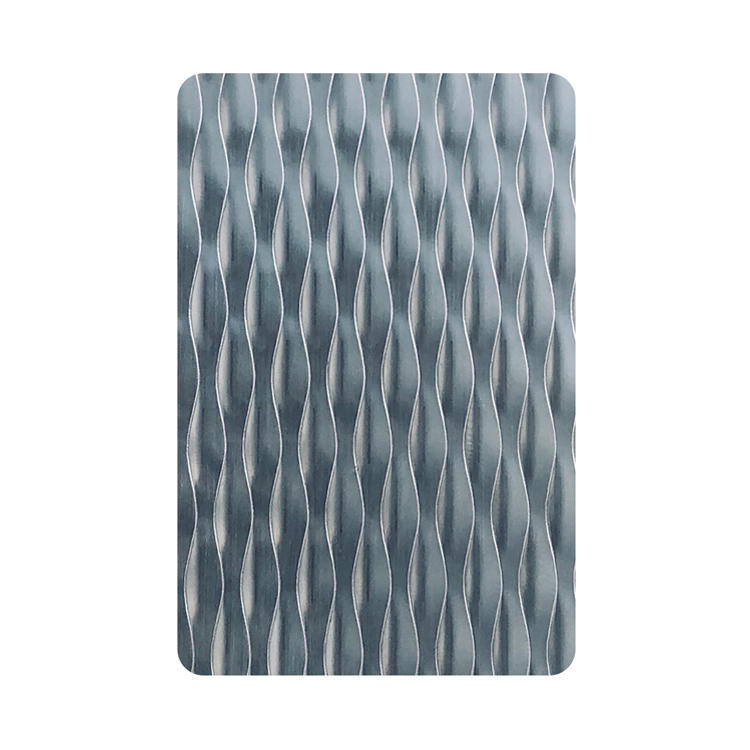

5WL Rigidized Stainless Steel Cladding Panel

5WL Rigidized Stainless Steel Cladding Panel

Proucts No.: MM-EM-5WL

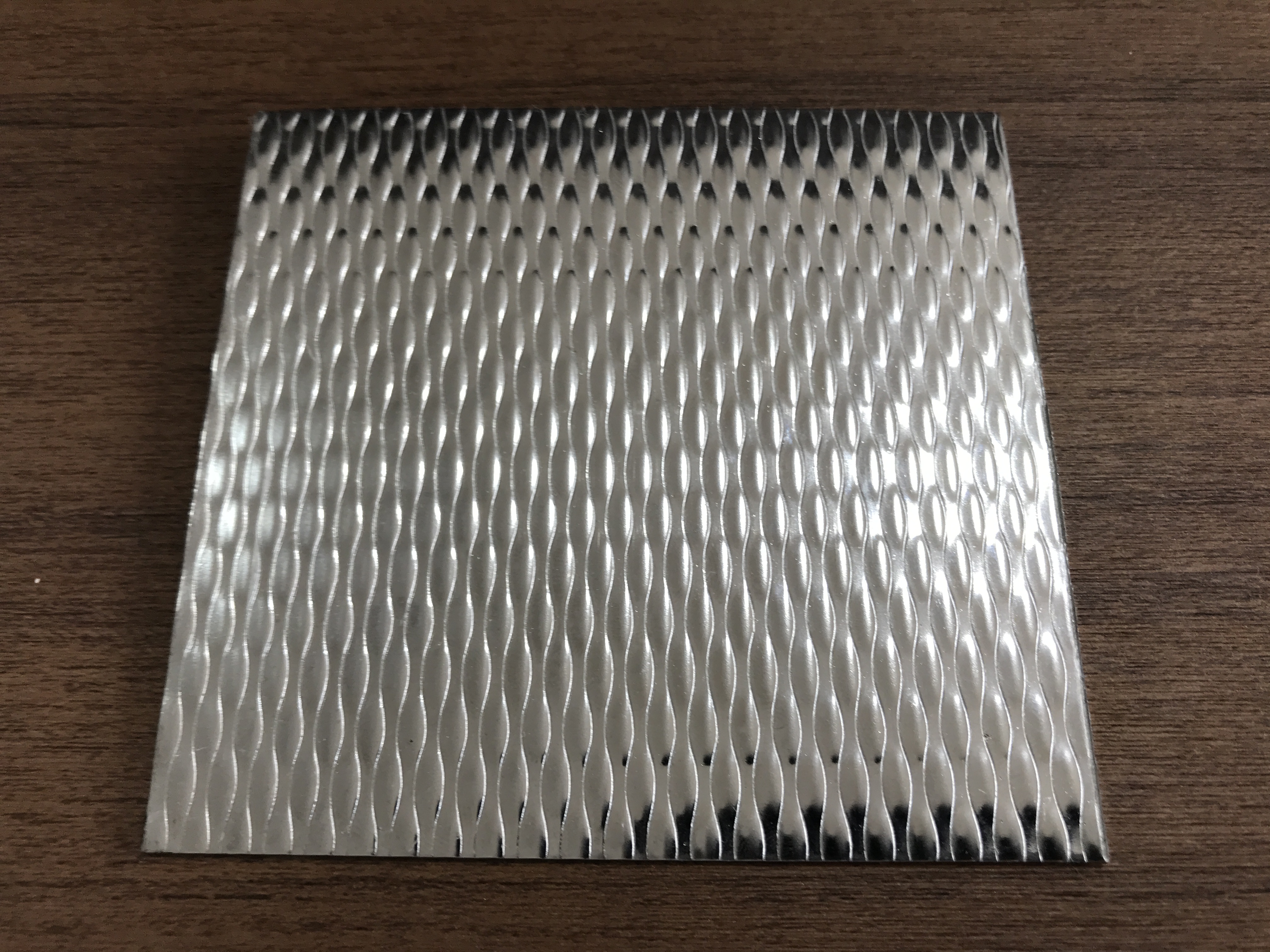

Sheet Grade: 304 / 316 / 201 / 430

Thickness Tolerance: within +/-0.03mm

Regular size : 4*8ft, 4*10ft, 1*2m, 1.5*3m

Standard : ASTM, AISI, DIN, EN, GB, JIS

Packing Details: PVC+ Waterproof Paper + Strong sea worthy wooden package

Delivery Time: 7 - 15 working days

Payment Terms: T/T, L/C at sight, Western Union

5WL Rigidized Stainless Steel Cladding Panel

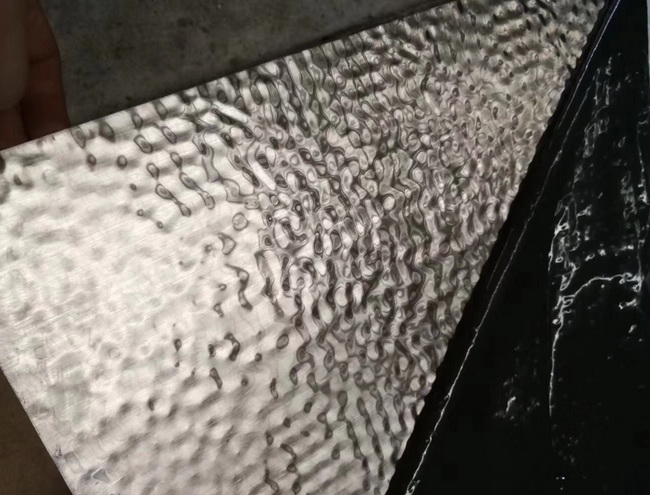

Embossed sheet metals have a very wide range of applications. They are used as masks, cladding panels for exteriors and interiors, fences panels and surfaces, gratings, stair platforms, stairs, to manufacture various products made of sheet metal.

MATERIAL:

All types of sheet metal (steel cold / hot rolled, galvanized, manganese, stainless steel, aluminum, copper, brass ...).

THICKNESS:

From 0.5 mm up to max 3mm, depending on the type of material and the embossing model.

DIMENSION OF SHEET AND PANEL:

Standard dimension for sheet metal is 1219x2438mm. Other standard dimensions: 1000x2000-1219x3048mm. We can produce also non-standard dimensions of sheet metal and panels (custom) according to customers drawings, with additional operations (bending, welding, surface protection).

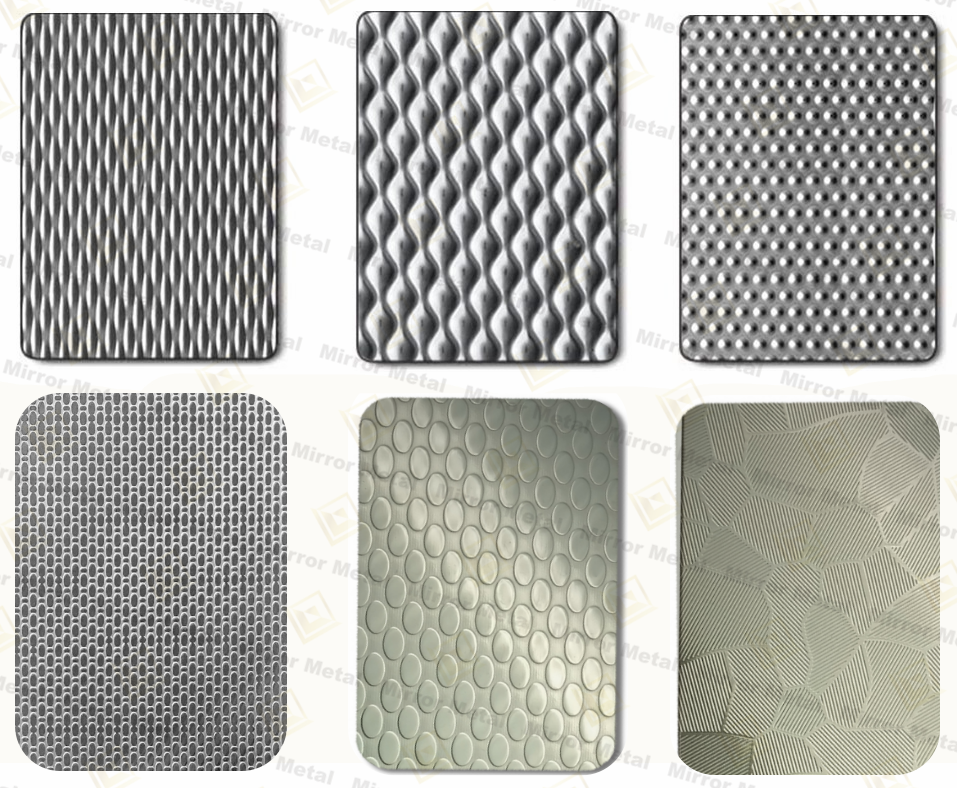

EMBOSSING MODELS:

Several models of embossed sheet metal are available. For more information on our various models and sheet thickness please contact with our team. If you have a specific request please send us relevant drawings, and we will produce embossed sheet metal according to your request.

MARGINS AND UNPERFORATED SURFACE:

Embossed sheet metal is usually produced with no margins. If a customer requires, we can produce embossed sheet metal with margins but it is necessary to consult our technical department about the feasibility and potential issues that may arise (i.e. problems with the flatness, wavy edge of sheet, etc...).

PRODUCTION VOLUME:

MIRROR METALS is specialized in manufacturing small and medium series and order. Also we are able to increase production capacity and accept large orders. Minimum quantity does not exist. Please send us an request for all kinds of products from our production program.

ADDITIONAL OPERATIONS AND SURFACE PROTECTION:

During embossing mechanical stress can cause sheet metal deformation at different levels, depending on the type of metal and embossing model. Deformations are corrected by mechanical roll levelling, which is a standard operation in production.

OTHER ADDITIONAL OPERATIONS ARE:

Corners outbreak

Accurate notching

Cutting

Bending

Bending of the semi-circle

Pressing

Welding

Send blasting

Powder coating

Please make sure your contact information is correct. Your message will be sent directly to the recipient(s) and will not be publicly displayed. We will never distribute or sell your personal information to third parties without your express permission.