Stainless Steel Decorative Screen

Stainless Steel Decorative Screen

Type:Screens & Room Dividers

Place of Origin:Guangdong, China (Mainland)

Brand Name:Mirror Metal

Model Number:Stainless Steel Decorative Screen

Material:Metal

Standard:GB/T 24001-2016, GB/T 19001-2016, ASTM, JIS, EN

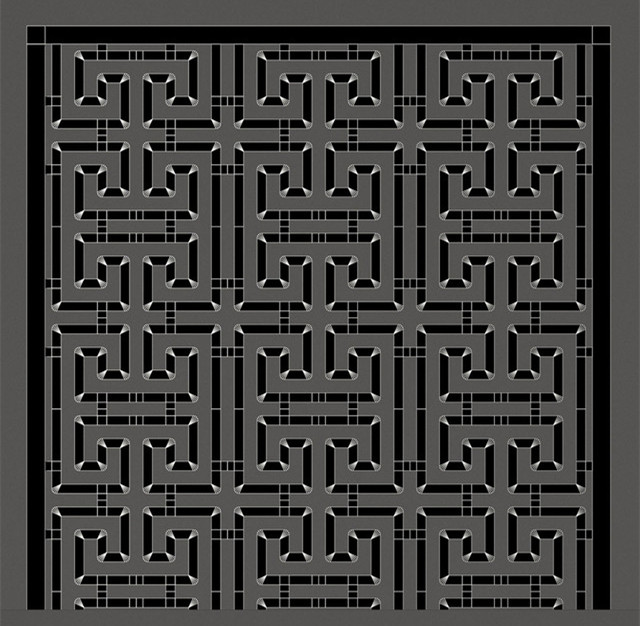

Thickness:0.8 mm – 3.0 mm.

Width:30mm-1850mm, Customized

Length:1220mm-3000mm, Customized.

Tolerance:±1%.

Technique:Cold Rolled.

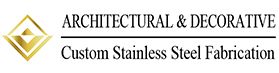

Finish:Powder Coating, Anodizing, PVDF Coating.

Metal Type:Stainless Steel / Alumimum

Color: Hotel Gold, Rosegold, Champagne Gold, Black, and Customized

Usage:Hotel

Application:Ceiling, Wall Panel, Facade, Interior Decorations.

Feature:Eco-friendly

Package:PVC + Waterproof Paper + Wooden Package.

Stainless Steel Decorative Screen

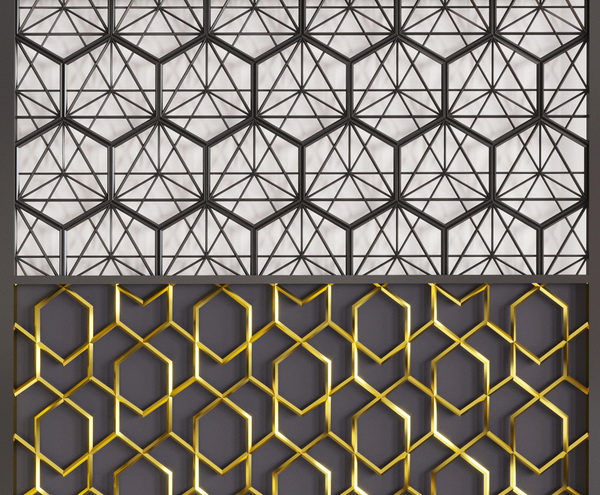

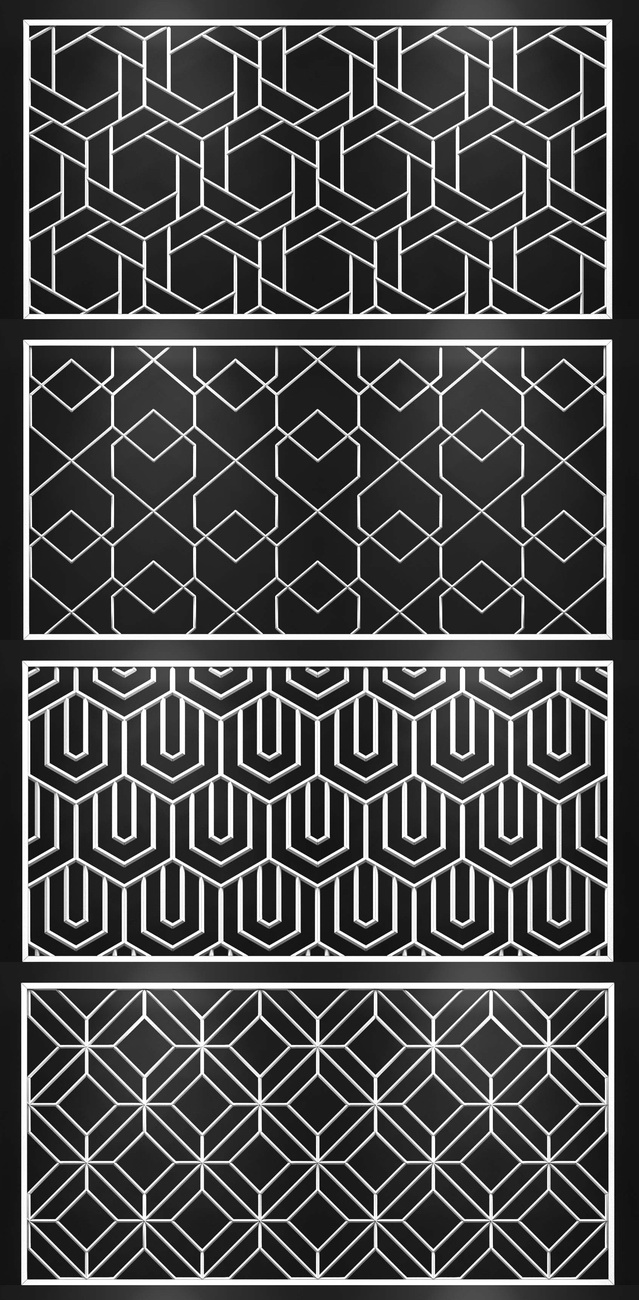

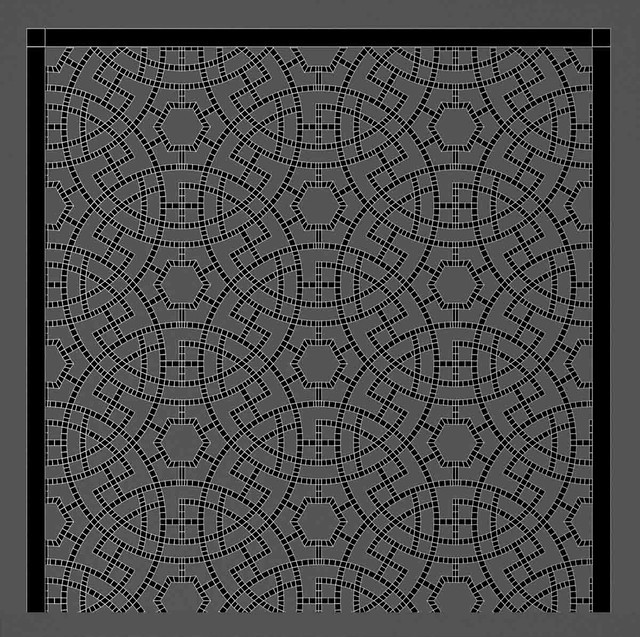

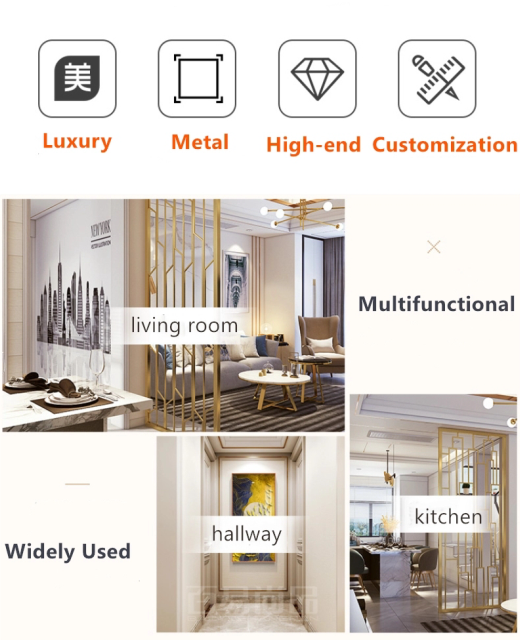

The stainless steel laser cut screens and panels are more and more popular in modern interior design.

Compared with other material of partitions, the stainless steel screens have unique corrosion resistance and high temperature resistance, which are more suitable for modern style decoration, including hotels, bars, restaurants, leisure, offices, financial institutions as well as luxury residences and apartments.

Metal Options for Laser-Cut Screen Panels

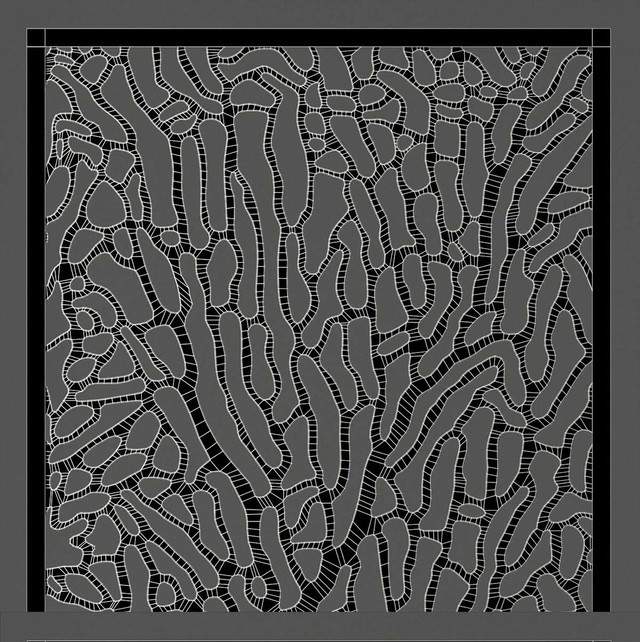

Laser cutting is used to create screen panels from several different metals copper, brass, stainless steel, aluminum, and steel. Different metals have their specific property and characteristics, for instance, steel has strength while copper gives it a warm touch and they cover a wide range of design opportunities for any project.

Stainless Steel

From this perspective, it has a special feature of corrosion and can be recommended where the metal material will be used in an open area or high humidity. It may be polished to some smooth finish or just rubbed to produce this elegant appearance.

Aluminum

Aluminum has low density, does not rust, and is very suitable for inside and outside applications. Its finishes anything from the raw metallic look to the anodized or powder coat complete means there are many choices in terms of function and look of the frames.

Steel

Aluminum has low density, does not rust, and is very suitable for inside and outside applications. Its finishes anything from the raw metallic look to the anodized or powder coat complete means there are many choices in terms of function and look of the frames.

Copper

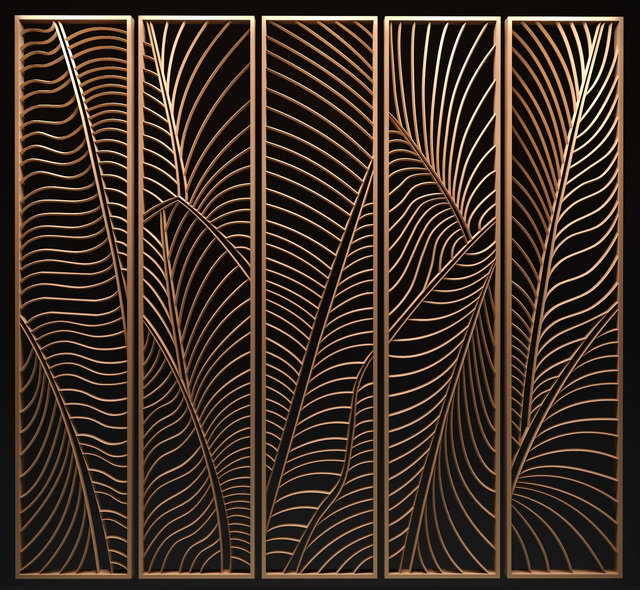

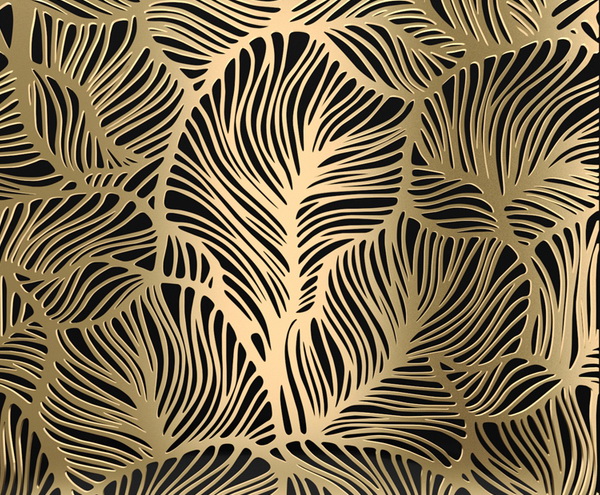

The copper panels with the laser-cut patterns also get a beautiful warm tone and esthetics; however, creating verdigris. It contributes elegance and character in numerous designs, in everything that aims for a country feel, or a glamour feel.

Brass

Brass is glamorous when it is refined and permanent at the same time and when polished can cast an aura of enchanting charm. As time goes on it gains a rather peculiar appearance, which increases the hardly ever-changing beauty of the craft.

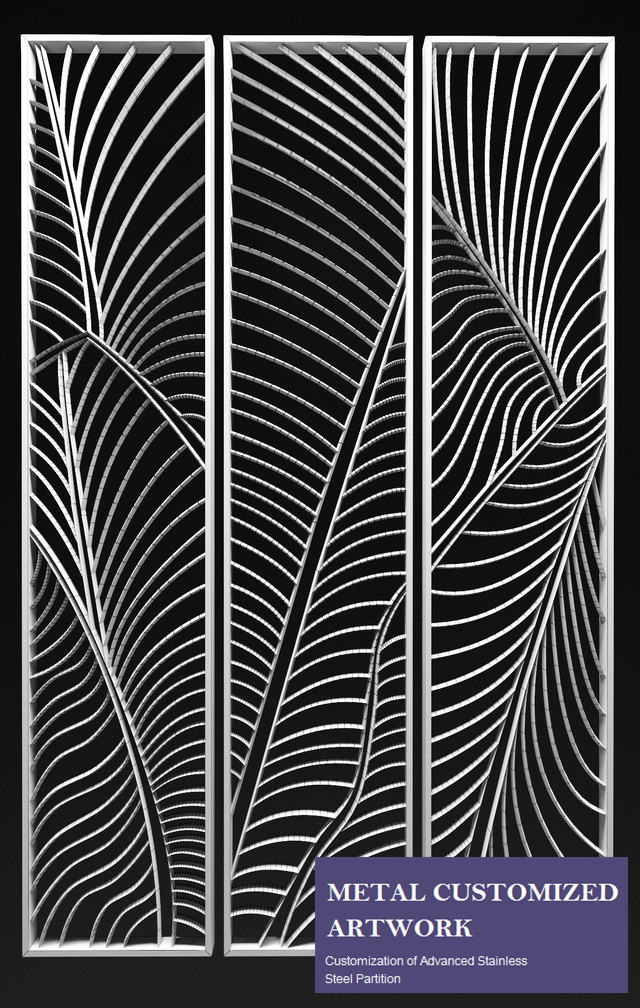

- Customer sends picture or CAD design to us, we make detailed drawing/ 3D mold and show to clients for confirmation.

- Making exact screen according to the CAD design .

- Cutting//Bending/Welding/PVD/Polishing as needed.

- Take different views pictures/ videos and show to clients.

Why Choose Laser-Cut Metal Screen Panels

for Your Project

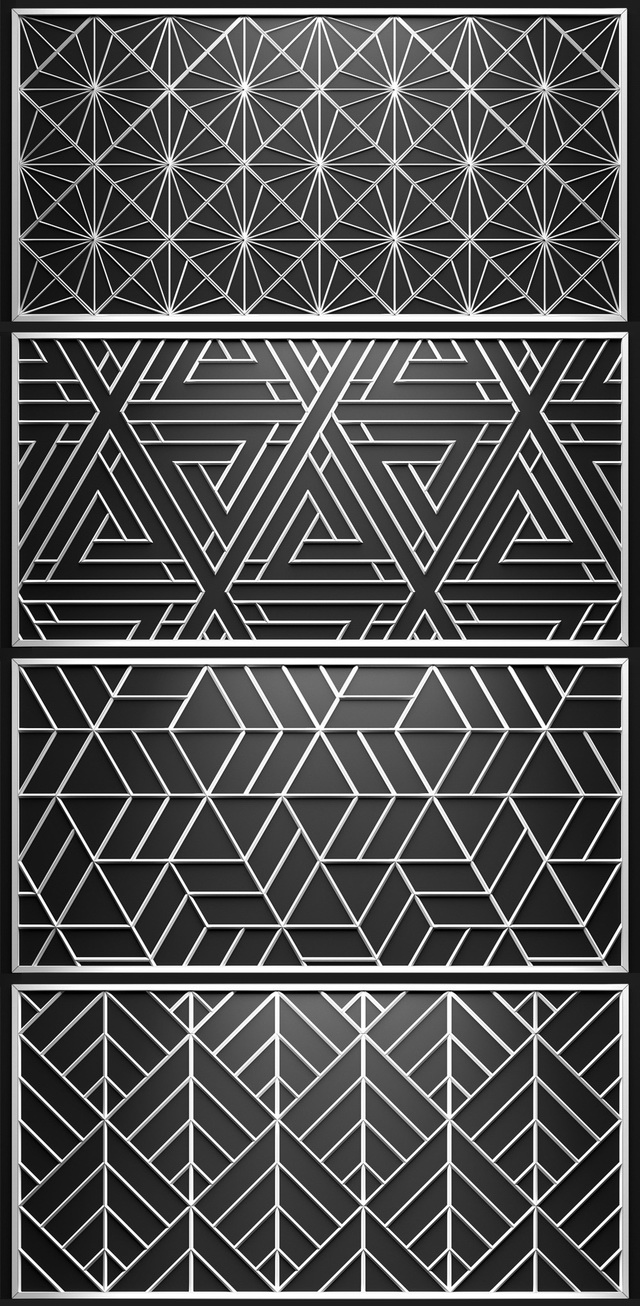

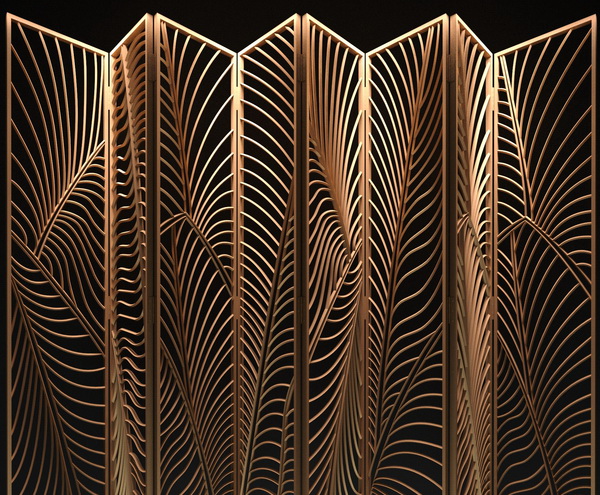

Laser cutting in particular has given metal from screens acclaim because of its flexibility and beauty in design projects. From their appearance and complexity in the manner in which they make up walls and entire spaces, then the way they make divisions possible to manipulate light in certain ways and create privacy, they are in both ways.

Laser-cutting technology is adopted in the production of near-critique designs and unique designs uniquely for every innovative project. Thus, phenomenal patterns and themes on the metal screens are made possible by the use of laser cutting.

Such panels are quick to enhance the appearance of any zone since they come across as large visual features. They give compositions depth and texture and become objects that attract the viewers’ attention and make them remember something.

The laser-cut patterns are clear when cut to the panels are backlit or placed under natural light to offer an excellent touch of light and shade. Such contrast of lighting and shading creates depth, drama, and the feeling of activity from relative environment.

Laser-cut metal screens give privacy yet allow for airflow and light to pass through the screens. It is possible to use them as partitions or room dividers to provide practical separation when the space should remain as linked at first sight as possible.

Laser cutting on metal screens that are fitting to be used both in interior and exterior zones. They add beauty to the internal spaces and also are resistant to weather conditions thus can be used in external designs such as facades, pergolas, or fences.

These panels are not a rarity to be made out of a strong material such as stainless steel or aluminum making them have durability. They do not rust, scratch, fade, or wear out fast hence suitable for use in either residential or commercial property.

The maintenance that has to be done on the metal screens after laser cutting is not much. These kinds of displays have been proven quite useful especially in business settings because they only require routine washing and overall check-ups at times.

This flexibility allows laser cutting in panels to be designed according to the project necessities and on an individual basis. They come in size, shape, pattern, and finish which makes it possible to design special and individualistic products for areas of use.

Please make sure your contact information is correct. Your message will be sent directly to the recipient(s) and will not be publicly displayed. We will never distribute or sell your personal information to third parties without your express permission.